Modeler- Tyler

Plugging in values into the simulation to model various energy saving outcomes.

Results:

One Drexel Plaza before:

One Drexel Plaza After bringing it up to code:

Total Energy [kWh]

|

Energy Per Total Building Area [kWh/m2]

|

Energy Per Conditioned Building Area [kWh/m2]

| |

Total Site Energy

|

1113795.53

|

223.56

|

223.56

|

Net Site Energy

|

1113795.53

|

223.56

|

223.56

|

Total Source Energy

|

3605193.92

|

723.62

|

723.62

|

Net Source Energy

|

3605193.92

|

723.62

|

723.62

|

Total Energy [kWh]

|

Energy Per Total Building Area [kWh/m2]

|

Energy Per Conditioned Building Area [kWh/m2]

| |

Total Site Energy

|

792216.48

|

159.01

|

159.01

|

Net Site Energy

|

792216.48

|

159.01

|

159.01

|

Total Source Energy

|

2746383.66

|

551.24

|

551.24

|

Net Source Energy

|

2746383.66

|

551.24

|

551.24

|

Piezoelectric Systems- Rahul

The word piezoelectricity means electricity resulting from pressure. basic piezo sensor is often used for flex, touch, vibration and shock measurements. Converting energy from mechanical stress and load is one of the most promising ways to integrate the energy harvesting module, thanks to the high power density of piezoelectric materials.

Israeli engineers are about to begin testing a 100 metre stretch of roadway embedded with a network of Piezo Electric Generators (IPEG™). The piezoelectric effect converts mechanical strain into electrical current or voltage and the system is expected to scale up to 400 kilowatts from a 1-kilometre stretch of dual carriageway. Innowattech's generators are embedded at a depth of about 5 cm; the area where the compression stress is maximal. For our

Israeli engineers are about to begin testing a 100 metre stretch of roadway embedded with a network of Piezo Electric Generators (IPEG™). The piezoelectric effect converts mechanical strain into electrical current or voltage and the system is expected to scale up to 400 kilowatts from a 1-kilometre stretch of dual carriageway. Innowattech's generators are embedded at a depth of about 5 cm; the area where the compression stress is maximal. For our

Green roofs are not only aesthetically pleasing, but they also:

Reduce city “heat island” effect

Reduce CO2 impact

Reduce summer air conditioning cost

Reduce winter heat demand

Potentially lengthen roof life 2 to 3 times

Treat nitrogen pollution in rain

Negate acid rain effect

Help reduce volume and peak rates of stormwater

N/A

Reduce city “heat island” effect

Reduce CO2 impact

Reduce summer air conditioning cost

Reduce winter heat demand

Potentially lengthen roof life 2 to 3 times

Treat nitrogen pollution in rain

Negate acid rain effect

Help reduce volume and peak rates of stormwater

Lights-Shi Yuyang

N/A

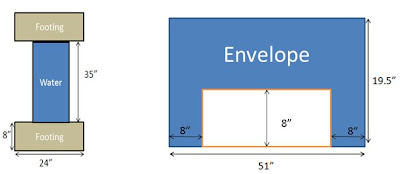

Water turbines- Karan